Our products

Here are all our products shown. If you have any questions about certain product or application, please contact us, so we can help you.

Here are all our products shown. If you have any questions about certain product or application, please contact us, so we can help you.

Permacol CA 3030

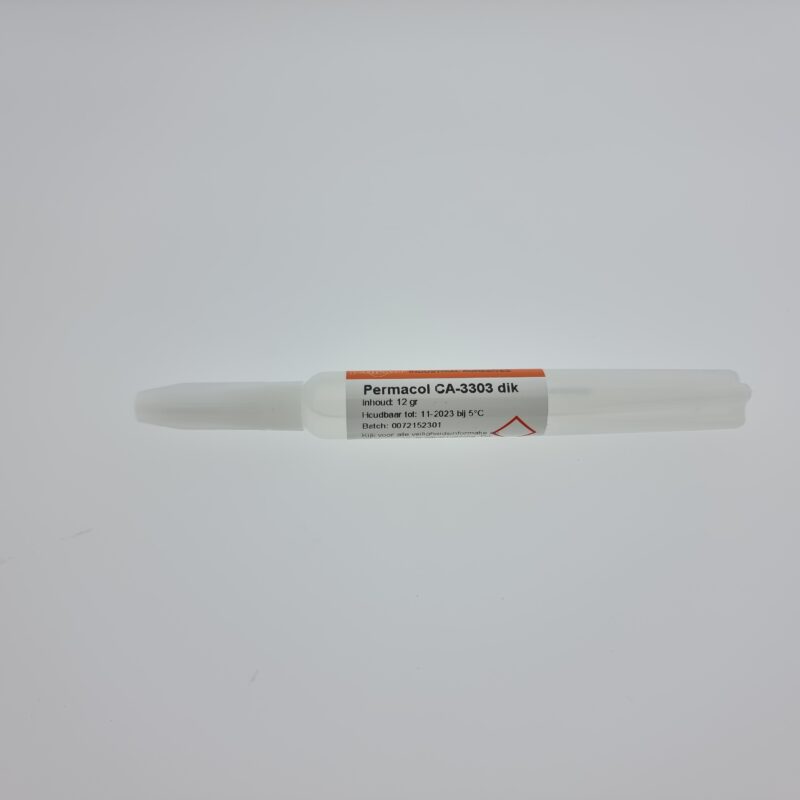

Permacol CA 3303

Permacol CA 305

Permacol CA 302FS

Permacol CA 301

Permacol 3720

Permacol 2245

Permacol 2163

Permacol 2242

Permacol 5277 UV

Permacol PX-3

Permacol 3000-Series

Permacol 3510-Series

Permacol 3525

Permacol 3526

Permacol 3527

Permacol 3522

Permacol 3719

Permacol PC30

Permacol SilGrip 529

Permacol RTV 615

Permacol RTV 664

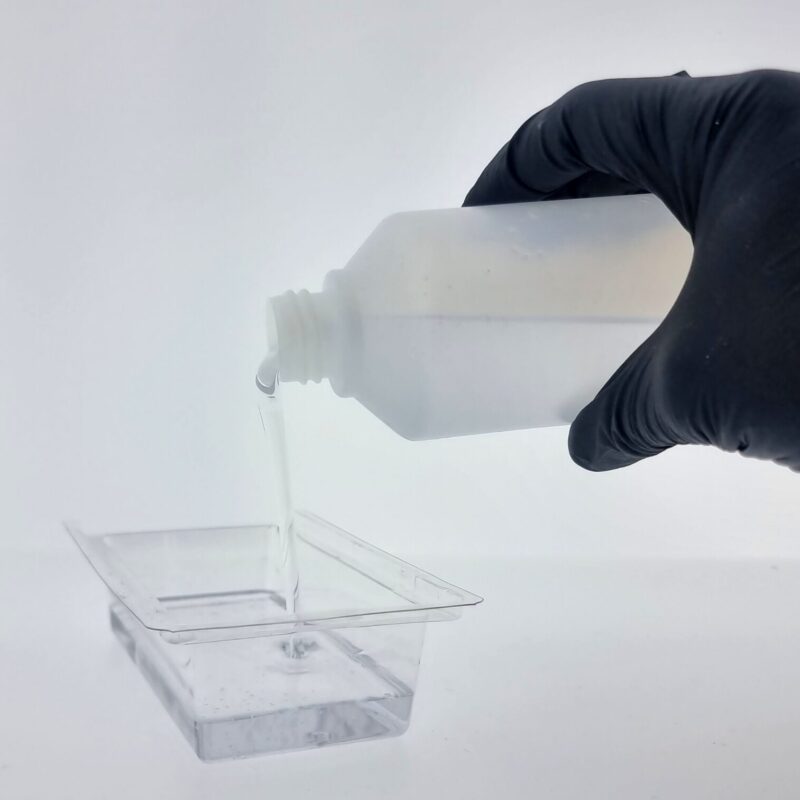

Isopropanol (IPA)

Permacol 2040-Series

Permacol 2177

Permacol 2032-Series

Permacol 2206-Series

Permacol 2220

Permacol 2252

Permacol 2369-Series

Permacol 2505

Permacol 2510

Permacol 2812

Permacol 2855

Permacol 5132-5133

Permacol 5134

Permacol 5196-Series

Permacol 5198-Series

Permacol 5450

Permacol 5663